1. Maginito a neodymium nthawi zambiri amapangidwa kuchokera ku ufa wa neodymium, chitsulo, ndi boron womwe umayikidwa palimodzi pansi pa kutentha kwakukulu ndi kukakamizidwa kuti apange mankhwala omalizidwa.

2. Chisakanizo cha ufa chimayikidwa mu nkhungu kapena chidebe ndikutenthetsa kutentha kwapamwamba kuti ayambe kusungunuka ndi kusakaniza.

3. Zinthu zikafika posungunuka, zimasungidwa kutentha uku kwa nthawi ndithu mpaka zitakhazikika mu chidutswa chimodzi popanda mipata kapena ming'alu pakati pa tinthu tating'onoting'ono.

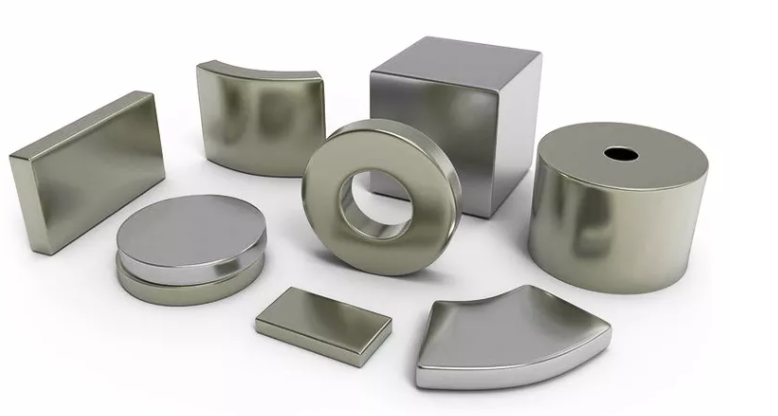

4. Pambuyo kulimbitsa kwachitika, maginito amatha kupangidwa mu mawonekedwe ndi kukula kwake komwe akufuna kugwiritsa ntchito zida zosiyanasiyana zodulira monga makina opangira mphero kapena lathes malingana ndi ndondomeko ya ntchito.

5. M'mphepete mwa maginito amatha kupukutidwa mosalala ngati angafune asanakutidwe ndi plating zoteteza monga faifi tambala kapena nthaka kuti musachite dzimbiri.

Zambiri pokonza, chonde onani tchati chomwe chili pansipa:

| Ayi. | Njira Yoyenda | Njira Yopanga | Ntchito zamakono |

| 1 | Kuyang'anira Zinthu Zopangira | 1.ICP-2.chemical Analysis-3.Analyser(C&S) | Kuzindikira kwa Rohs Mayeso Opanga Purity Analysis |

| 2 | Chithandizo cha Raw Material Pre-treatment | 4.Sawing- 5. Kuyanika- 6.Impact Cleaning | Sawing Iron Kuyanika Mpweya Wotentha Impact Cleaning |

| 3 | Kuwongolera Zosakaniza | 7.Ingredient Control | Weight Batching Sakanizani Raw Material |

| 4 | Strip Casting | 8.Vacuumizing-9.Kusungunula-10.Kuponya | Vacuuming Kusungunuka Kusungunula Kuponya |

| 5 | Kuchepa kwa Hydrogen | 11.Pre-treating-12.Vacuumizing-13.Onjezani Hydrogen | Kuchiza koyambirira Vacuuming Kuwononga ndi haidrojeni |

| 6 | Kugaya | 14.Kuphwanya-15.Kugaya-16.Jet Mill-17.Granularity Control | Kuphwanya Kupera Jet Mill Muyezo Wokhazikika |

| 7 | Kukanikiza | 18. Kulemera kwa ufa -19.Pre-pressing - 20.Pressing -21. Isostatic kukanikiza | Kulemera kwa ufa Kukanikizatu Kukanikiza Isostatic kukanikiza |

| 8 | Sintering | 22.Vacuumizing- 23.Sintering -24 Chithandizo cha kutentha | Vacuuming Sintering Kutentha mankhwala |

| 9 | Kuyendera | 25.BH poto-26. PCT-27. Kuyesedwa kwa kachulukidwe -28.Roughcast Inspection | Kuyeza kwa maginito Kutentha kwa coefficient test PCT Kachulukidwe Muyeso Kuyendera |

| 10 | Machining | 29.Kupera -30.Kudula waya-31.Kudula kwamkati | Kupera Kudula waya Kudula tsamba lamkati |

| 11 | Chitsanzo cha mayeso a QC | 32.QC chitsanzo cha mayeso | Chitsanzo cha mayeso a QC |

| 12 | Chamfering | 33.Kukonda | Chamfering |

| 13 | Electroplating | 34. Electroplating Zn 35. Electroplating NICUNI 36.Phosphating 37. Chemical Ni | Electroplating Zn Electroplating NICUNI Phosphating kapena Chemical Ni |

| 14 | Kuyang'anira Coating | 38.Kunenepa-39.Kukaniza kwa Corrosion -40. Adhesiveness-41.-Kulekerera Kuyendera | Makulidwe Kukaniza kwa Corrosion Kumamatira Kulekerera Kuyendera |

| 15 | Magnetization | 42.Kuyendera kwathunthu- 43.Kulemba- 44.Kukonza/Kusintha- 45.Maginito. | Kuyendera Kwathunthu Kuyika chizindikiro Kupanga / Kusinthika Maginito Magnetic Fiux Test |

| 16 | Kulongedza | 46. Magnetic Flux- 47.Bagging- 48. Kunyamula | Kunyamula katundu Kulongedza |

Nthawi yotumiza: Feb-15-2023